What is Warehouse Management System(WMS)? [Process + Benefit + Types]

Are your profit margins getting chopped away by the supply chain? Maybe, you have no inventory insight, or you simply lack a custom warehouse management system (WMS)! While this seems like a quick fix, it really provides a foundation for your business operations. You will add new feet to the sales of your company with a smarter warehouse system, especially with cloud storage technology.

However, there’s more. So, let’s harness this power of innovation together and improve operations. We have explained each bit of WMS in this guide. So keep reading. Let’s start with the basics, what is wms?

Table of Contents

What is WMS(Warehouse Management System)?

Warehouse Management System is a software solution that helps to monitor and handle the day-to-day tasks of a warehouse. WMS systems allow companies to control and oversee third-party logistics processes.

You may plan to build the WMS software as a standalone program or part of a framework for Enterprise Resource Planning (ERP).

How Does a Warehouse Management System Work?

To understand WMS, you first need to recognize its process, which can be classified into the following steps.

Inventory Management

- Step 1. Receive Goods: When you place an order, WMS stores the details of all the vendors in one location and synchronizes it to real inventory levels, making it easier to handle procurement. By merely checking the barcode, the commodity will be added to the order. The orders are then emailed directly from the device to the retailer.

- Step 2. Inbound Receipts & Put Away: WMS-integrated scanning systems optimize receipt and direct workers to the right place to shelve the items. Depending on the type and characteristics of products, WMS can also recommend different techniques for slotting, put away, and the best use of the storage space.

- Step 3. Track & Allocate Stock: The WMS lets managers know the quantity of product available and when restocking is required. Along with the use of minimum and maximum levels, this allows the company to order more stock at the right time and in the right quantity to reduce shortages and thus, keep the inventory from being overstocked.

Order Management

- Step 4. Picking: Picking is the process of collecting items according to the customer’s order from the storage site. This can be painful, but an effective WMS guarantees that the best product is chosen, using simple methodologies or company guidelines such as FIFO (first-in-first-out). Also, Barcode scanners or RFID scanners help with the order accuracy of getting the right WMS products.

- Step 5. Packing: The type and quantity of packaging are determined by WMS automatically and an optimum packing process is proposed. UPS, FedEx, and USPS shipping labels (as well as price tags, logos, and other necessary documentation) may be printed straight from the machine, so there is no need to manually input addresses or re-type tracking numbers.

- Step 6. WIP (Work In Progress): A customized WMS will also track whether the packed product is in progress or in transit. This can be helpful to keep updating your customers about their product and shield the trust. Also, in a situation where the packages are lost, broken, or theft, managers can easily identify and solve the issue.

- Step 7. Shipping: WMS program then helps to make sure your orders are delivered on schedule to the right customers and notifies them about the same. Also, thanks to the prevention of errors made at the selection and dispatch periods. Because your transportation management systems made effective and less expensive for inbound and outbound order fulfillment with the program.

- Step 8. Returns: By automating every step like making the return, documenting the purpose, upgrading the stock, granting complete or partial refunds, and producing reports, WMS will help streamline this unpleasant process.

Reporting & Analytics

- Step 9. Safety Control: WMS will keep tracking of what is going on in the warehouse to ensure safety by monitoring the location of workers, marking incoming truck license plates, restricting access to certain locations, etc.

- Step 10. Reporting: Customizable analytics will provide a report on all the details and recognize your most profitable client, top-selling commodity, best-performing sales channel, most productive worker, yard management details, and peak sales season.

Want to optimize your warehouse functions with mobile solutions?

Next, you would learn what are the advantages of a warehouse management system.

Benefits of Warehouse Management Systems (WMS)

Optimized Processes

Building the right WM solution for your organization would help you to refine the processes inside the warehouse smoothly. That means not only having the best processes to suit the organization itself, but also those that suit the type of products that you handle. An intelligent collection of WMS would allow you to implement a number of algorithms, including wave, region, and batch picking.

Inventory Visibility

Using warehouse inventory management system with scanning, RFID, or other location-tracking solutions guarantees visibility and eliminates non-WMS-enabled situations where the inventory inside the warehouse is forgotten, lost, or misplaced. This encourages a business to estimate supply more securely and avoid backorders, which leads to more happy customers.

Reduced Admin Work

All administrative work that historically involved reams of paperwork and data processing is streamlined and organized by the WMS solutions. With inventory data available at your side, results can be analyzed and released in seconds.

Improved Supplier and Customer Relationships

When the warehouse management software handles your product inventory and multiple locations, it ensures that you get the right product, on the right vehicle. This system-driven productivity allows you to minimize tension with your supplier partners or even end-users.

Reduced Labor Costs

The WMS solution will automate most warehouse operations to a greater degree. It is also possible to rationalize workforce capital and delegate them to the most appropriate duties while saving time wasted on labor-intensive operations. This allows organizations to reduce needless employee costs and improve the quality of the current workforce with labor management.

Enhanced Security

A modern WMS software will enable warehouse staff to use their own special user account to enter transactions. This results in an audit trail that links transfers of that individual employee. It helps to minimize wastage and other ways of shrinkage when transparency is in place, as well as to highlight opportunities for coaching and more rigorous preparation.

Need WMS software experts who understand your customers?

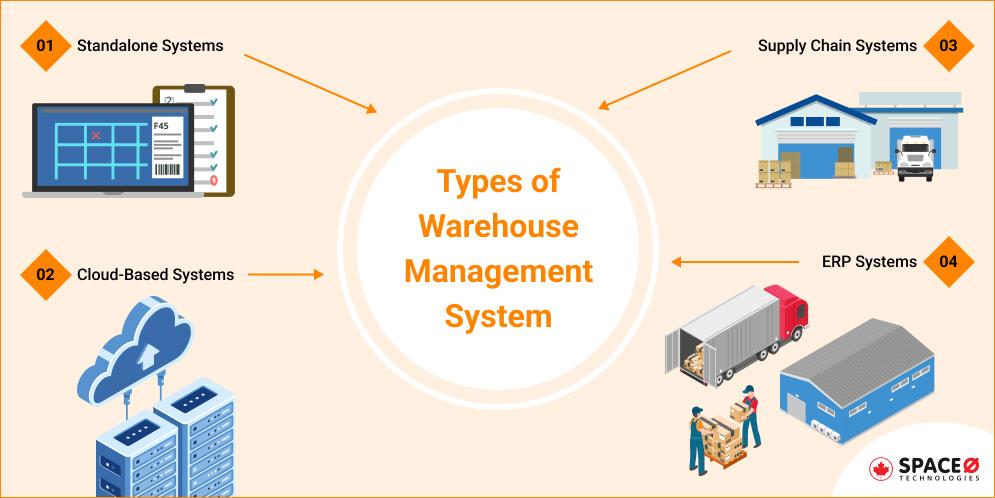

Types of Warehouse Management Systems

There are several types of warehouse management systems, but companies need to find a suitable WMS that helps their warehouse activities in order to handle and monitor regular operations. So let’s take a look at each.

Standalone Systems

A standalone WMS is the standard software of the sort on-premises system that is installed on the company’s native hardware and network. Many WMS applications are third-party packages that need to be combined with the rest of the organization’s management applications (such as the ERP system).

It is ideal for,

- All small-sized businesses

- Limited software budget

Pros Cons - Advanced warehouse management system features

- Integration capabilities

- Improved customer service

- Siloed software

- Lack of real-time visibility

- High cost

Cloud-Based Systems

A web-based, centralized-computing model using cloud technologies is generally knowns as cloud-based WMS. The cloud-based system development is also famous for its fast scalability and rollout. It can have the same advantages as a more conventional WMS while offering quicker chain execution and lower inventory costs. The cloud based warehouse management system does not require installation and synchronization with native hardware and networks, because they are web-based.

It is ideal for,

- All size of companies

- Businesses with multi-location needs

Pros Cons - Quick implementation

- Easy to use platform

- Cost-effective

- Best practices & customer successes

- May lack a variety

Supply Chain Management Systems

Technology for supply chain management system development is much wider in nature (WMS is essentially an SCM subcategory) and can support customers in handling multiple facets of the supply chain visibility. To automate the monitoring of inventory replenishment, inventory cycles, material procurement, and other typical activities are the primary focus of supply chain management. However, it can also accommodate risk analysis, current market operations, and vendor partnerships.

It is ideal for,

- Small to medium size of companies

- Businesses with multiple supply chains

Pros Cons - Focus on business aspects and supply chain operations

- High flexibility

- Satisfy consumer needs

- Material handling equipment

- Unanticipated operating costs

- Integration difficulties

ERP Systems

Enterprise Resource Planning (ERP) software is a program used to monitor the resources of the whole business or organization. Some of the ERP program developments offer a WMS software or SCM module integrated into their ERP system, in addition to main applications, such as human resources software systems, sales and marketing, finance and accounting, and CRM solutions.

It is ideal for,

- All size of companies

- Business with varied customer requirements

Pros Cons - High visibility

- Improved reporting and planning

- Great customer relationship management

- High implementation costs

Can’t decide which system is suitable for your business?

Share your requirements with us and our experts will guide you further.

Cloud-based Warehouse Management System and Its Advantages

In a head-to-head WMS system comparison, our experts have found out that the cloud-based system is something that will empower the world in a short span. As moving to a scalable cloud-based WMS system enables a quick, cost-effective transformation and enhanced warehouse efficiency, your software will always be up-to-date. So let’s quickly move on to its significant benefits for your business.

Cloud Will Increase Cybersecurity

Cybersecurity is an integral part of any efficient Internet-leveraging mechanism and web-based operation. While cybersecurity doesn’t sound like a huge issue for the modern digital warehouse, retaining customer trust and building brand awareness is still essential. So, with the cloud framework, without the expenditure and implementation costs of enforcing cybersecurity policies in your sector, your business may easily take advantage of cybersecurity initiatives and protocols.

Cloud-Based WMS Offers Fast Process

As cloud-based systems run with wide scalability in a neutral environment, the systems have faster computing capacity. In other words, downtime in the e-commerce world, which is the difference between customers buying for your business or dumping their purchases, is less likely to negatively affect client interactions.

Cloud Can be Accessed at Anywhere in Real-time

Being able to view shipment information on the go is commonplace now. Although self-hosted servers are feasible, organizations typically tend to shy away from providing internet access to their internal networks due to security issues. But, cloud-based inventory management solutions offer visibility on the client side and can save a significant amount of time.

No Limit on Scalability

Scalability is the first challenge posed by a traditional warehouse approach. These networks lack the ability to increase the number of controlled SKUs and result in bottlenecks and delays in delivering orders as SKU proliferation progresses. However, the warehouse management cloud, meanwhile, delivers near-limitless capabilities, combining the tools and best enterprises with those of any scale.

No Charges on Updating WMS

Most of the cloud-based services offer free upgrades over the usage period of the deal (weekly, monthly, yearly). This usually means that without having to expend any resources, the warehouse management cloud will continue to develop. That implies you will be always on the latest model of the app for a cloud-based approach.

5 Reasons to Go for Custom-Built Warehouse Management System

As we all know, whether to buy ready-made or build a custom program for your business size is a long debate, but we have settled down this topic with the 5 most significant reasons to build a custom program that you can’t ignore to look at it.

Automate All Types of Workflow

Based on whether you represent a single client or a wide variety of clients, warehouses are arranged differently. Hundreds of workflows occur in each team and department. And it’s a really tiring process to handle each workflow manually. Plus, no ready-made software solution can automate each type of workflow that is unique to your business size. So, such situations can be handled only with custom-built software as it provides an industry-specific solution that easily incorporates new functionality without interrupting the current workflow.

Guaranteed Compatibility

A lack of consistency is the greatest deal-breaker if your warehouse organization depends on several computing systems that need to exchange information. So, opposed to ready-made applications like oracle, build-your-own solutions often provide a major benefit in order to establish compatible integrations across the enterprise systems offered by various partners.

Enhanced Flexibility

Business always needs change, but most oracle or off-the-shelf software does not allow its features to be profoundly updated. So, flexibility is one of the strongest reasons to opt for customized warehouse software systems as it is quite simple to update custom software to handle the new business requirements and challenges that are associated with business growth.

Satisfy Customer Needs

WMS solutions that are off-the-shelf do not meet every need, that’s a fact. So when the system itself interrupts your business workflow, it would not support its clients and their needs effectively. Therefore, most businesses now tend to believe that custom software is only essential for their unique needs as it is capable to cater all complexities.

Boost Transparency

Any inventory app that is personalized is able to get reliable & straightforward information and can normally be accessed remotely from any internet-enabled smartphone. This allows manufacturers to schedule their manufacturing reducing lead time. Hence, this transparency helps organizations to provide a superior support program to consumers.

Ready to build custom-built WMS software? Want to share your idea?

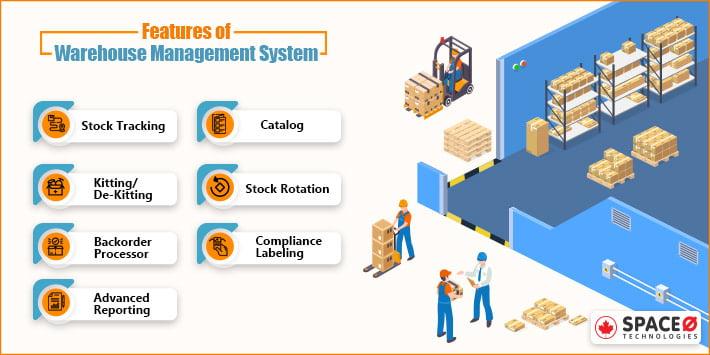

Key Features of a Warehouse Management System

Keeping the software functionality checklist on the top while building your custom solution will help you to bring the best results. So, here are some of the key features of the warehouse management system to integrate into your solution.

Stock Tracking

To maintain an optimum level of stock, this function helps to track goods between locations during shipment. You can also accept new merchandise & control warehouse processes such as picking, packaging, and delivery. Avoid product obsolescence & spoilage and ensure that your products are never out of stock.

Catalog

To quickly find inventory in your warehouse or through several warehouses, build SKUs, and identify attributes with the help of the catalog. Create new sales opportunities and reduce needless picking time, use SKU kits, packs, or assembled goods features, reducing human error.

Kitting/De-Kitting

Kitting functions help to generate work orders based on consumer needs, directing warehouse associates to merge multiple items to form a new object or turn an item into a new item. De-kitting can also process returned kitted goods and return components of the salvage kit to inventory.

Stock Rotation

This feature extends inventory management capability as it supports a variety of stock rotation requirements, lot number, receipt date, manufacture date, expiration date, and support for serial number tracking.

Backorder Processor

The Backorder system allows for more monitoring over the returned product, allowing companies to handle re-inspection, quality control, rework, repackaging, re-inventory, salvage, loss, or “return to seller” status as shipping or distribution failure the minute it occurs.

Compliance Labeling

If you are interfacing your WMS with compliance marking schemes, it helps to manufacture labels according to the desired consumer or carrier format.

Advanced Reporting

To make smarter purchase decisions, this function helps you to implement your wide variety of reports for topics such as replenishing Amazon stock or merely monitoring the factory floor customer transparency.

FAQ

What does WMS stand for in warehousing?

In warehousing, WMS is a program that stands for a warehouse management system software that helps to monitor and handle day-to-day warehouse tasks.

What is the concept of warehouse management?

Warehouse management is the process, monitoring, and optimization of warehouse operations from the entry of inventory into a warehouse or several warehouses.

What does the warehouse management system do?

The warehouse management system (WMS) is a solution that handles the warehouse or distribution center of inventory and activities.

What are the functions of the warehouse management system?

- Receive & tracking inventory

- Pick, pack, and ship

- Paper-less documentation

- Reports and analytics

What are the types of a warehouse management system?

- Standalone WMS

- Cloud-based WMS

- Supply chain system

- ERP systems

Why would we need a warehouse management system?

- To control the inventory

- To track stock

- To improve customer services

- To enhance the company’s productivity

- To gain greater ROI

What’s the difference between warehouse management and inventory management?

Warehouse management solutions provide a more holistic framework that covers all facets of operating and developing business warehouse systems, while inventory management takes a simple approach to manage stock volumes.

What are the best warehouse management systems?

NetSuite WMS, Fishbowl Inventory, 3PL warehouse manager, Softeon, Infor SCM (supply chain), HighJump, Astro WMS, and Bright Warehouse are a few of the examples.

How to build WMS software?

- Identify the needs and roles

- Select the type of warehouse management software

- Find a software development company

- Build and deploy

Conclusion

Since warehouse operations can differ greatly based on the market and the particular business needs of each customer, it is important to fulfill each one of them. Such situations always demand customized supply chain solutions. So, do you also want to build a WMS software that is intuitive and easy to learn? Contact us and get a free quote. We, as a reputed software development company in Canada, build solutions that give real-time insights into each aspect of business operations to help your company grow and adapt to changing market conditions. So, hurry up and get a free consultation today!

Need a Warehouse Management System to Streamline Your Supply Chain?

Editor's Choice

Understanding Nearshore Staff Augmentation: Key Benefits and Growing Trends

What is the Manufacturing Execution System? (Benefits + Architecture)

What is Business Process Automation (BPA)? [A Detailed Guide]

All our projects are secured by NDA

100% Secure. Zero Spam

*All your data will remain strictly confidential.

Trusted by

Bashar Anabtawi

Canada

“I was mostly happy with the high level of experience and professionalism of the various teams that worked on my project. Not only they clearly understood my exact technical requirements but even suggested better ways in doing them. The Communication tools that were used were excellent and easy. And finally and most importantly, the interaction, follow up and support from the top management was great. Space-O not delivered a high quality product but exceeded my expectations! I would definitely hire them again for future jobs!”

Canada Office

2 County Court Blvd., Suite 400,

Brampton, Ontario L6W 3W8

Phone: +1 (437) 488-7337

Email: sales@spaceo.ca